Every registered slags site is the remnant of the whole set of furnaces known as a slag-pit furnace cluster.

Creation of these sets is the result of the once used metallurgical furnace type which served one method of iron casting only. The research has proved that there were two independent production methods practiced in two types of workshops. The first one is represented by the so-called unordered furnace clusters grouping from a few to several furnaces. The workshops worked on the borders of settlements and their production secured the needs of local communities. The second method aiming at mass production connected most probably with an external market is represented by large specialised workshops called ‘ordered’ furnace clusters grouping about 100 furnaces on average. The largest set of this type was discovered in Świętomarz in the Pawłów commune – it contained 231 furnaces.

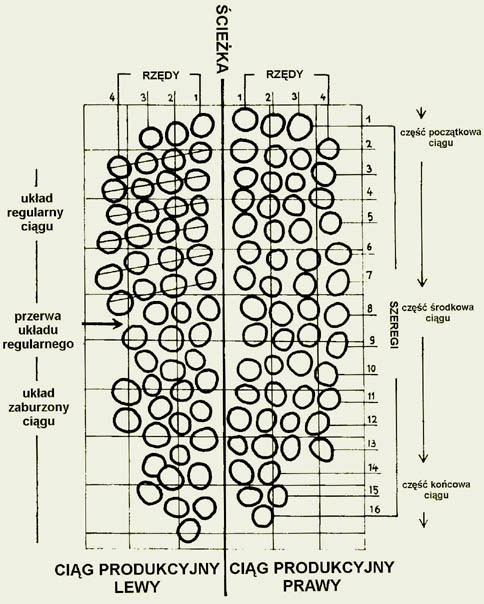

A characteristic feature of such workshops is a set of furnaces ordered geometrically forming twin groups the so-called ‘sequence’ separated by a ‘path’. Every such set – sequence - contained several rows with 2-5 furnaces in a row. Large ordered furnace clusters were usually located outside settlements even within long distances. Their location was mostly determined by close deposits of iron ore and easy access to a forest providing fire-wood. A furnace cluster of average size used most probably about 18 tons of iron ore, 20 tons of charcoal and could produce about 1,8 tons of iron.

Parts of the ordered furnace according to Kazimierz Bielenin