Reconstruction of a furnace cluster – an ancient slag-pit furnace workshop- linked the sites of ore specialists preparing iron ore, coal specialists dealing with charcoal burning, slag-pit furnace specialists supervising the iron casting process and smiths producing specific utensils.

The basic raw material used for the slag-pit furnace process is iron ore obtained in the area of old mining gobs in the vicinity of Rudki and Starachowice. Before iron casting ore undergoes a variety of processes aiming at elimination of harmful additions and initial preparation for the reduction process. The basic activity was breaking up of big blocks of ore which allowed separating the part of a barren rock which constitutes large part of ore. In order to remove clay and sand a widely used technique was ore washing. Finally ore was roasted on wooden piles called the ‘calciners’ to remove water and sulphur. In high temperatures ore pieces cracked and swelled enabling reduction gasses to access deep in the structure and thus a more effective reduction. In ancient times various ore types from our region were used, the preferred ones were easily melting limonite ores. For the purpose of presentation on a ‘slag-pit furnace cluster’ a reconstruction of a mining shaft from the mine in Rudki was prepared, the only known so far underground mine from the Roman times operating outside the borders of the Roman Empire.

Charcoal was the basic fuel used in the slag-pit furnace process. It was obtained by slow wood carbonizing with limited air access in structures called charcoal kilns. These were piles of appropriately ordered wood pieces covered with turf and earth. Charcoal kilns from the Świętokrzystkie Mountains were constructions partly hidden in the ground, having about 3 meters in diameter and depth not exceeding 120 cm. Botanical research of the coal from slag-pit furnaces indicate that various types of wood were carbonized, mostly the conifers (about 70%) such as pine trees and fir trees. From deciduous trees the most frequently used one was wood from beech trees, poplars and oaks. It is worth mentioning that carbonization process in charcoal kiln structures lasted at least 48 hours.

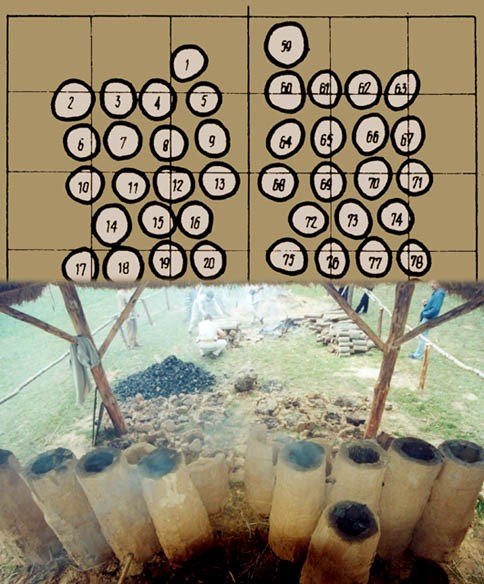

For the presentation of a slag-pit furnace set reflecting a real plan of a production workshop, in the year 2000 a reconstruction was prepared basing on one of the ancient slag-pit furnace clusters in Wieloborowice (compare photo and picture below).